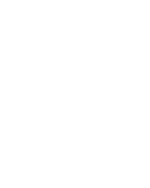

CX Wheel

- Description

These wheels are suitable for the hard- to-grind steel. Alloy mold steel SKD11、SKT1-6.High speed tool steel SKH2-10、SKH52-57。Powder metallurgy alloy steel ASP23、ASP30、ASP60 and so on.

- Manual

The unique microstructure of abrasive grain have better character of self sharpness and tough, suitable for grinding hard-to-grind material such as: ASP, SKD11, SKH. The fracture toughness of CX is only second to CBN.

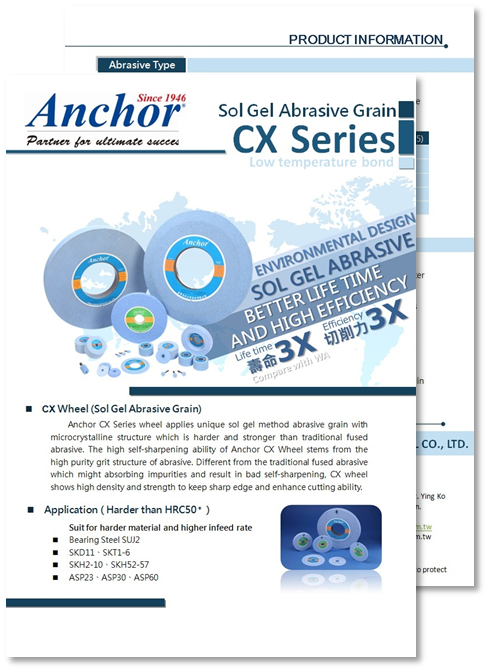

CX Wheel (Sol Gel Abrasive Grain)

Anchor CX Series wheel applies unique sol gel method abrasive grain with microcrystalline structure which is harder and stronger than traditional fused abrasive. The high self-sharpening ability of Anchor CX Wheel stems from the high purity grit structure of abrasive. Different from the traditional fused abrasive which might absorbing impurities and result in bad self-sharpening, CX wheel shows high density and strength to keep sharp edge and enhance cutting ability.

Application ( Harder than HRC50〫) Suit for harder material and higher infeed rate

PDF Download – CX grinding wheel

PDF Download – CX grinding wheel

- Bearing Steel SUJ2

- SKD11、SKT1-6

- SKH2-10、SKH52-57

- ASP23、ASP30、ASP60

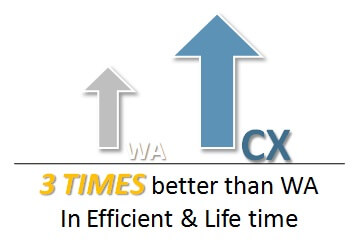

- Long life time : The test data shows that CX grinding wheel is 3 times better than WA grinding wheel in life time.

- Energy saving : CX grinding wheel is more durable and less prone to blunts while grinding. It constantly creates new sharp edges by the dropping out of microcrystalline ceramic grits。

- High efficiency : High efficiency on harder material and higher infeed rate grinding process. Longer dressing interval.

- Low grinding heat : The high self-sharpening of CX grinding wheel results in good heat dissipation to avoid burning.

PDF Download – CX grinding wheel

PDF Download – CX grinding wheel - Inquiry