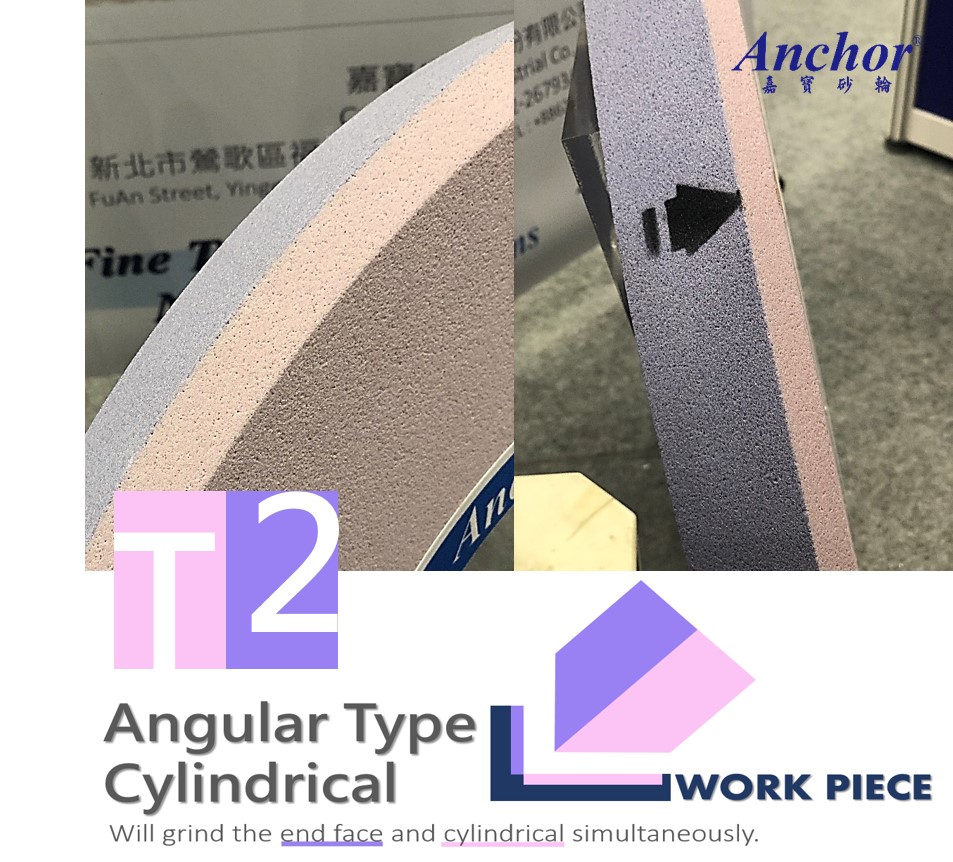

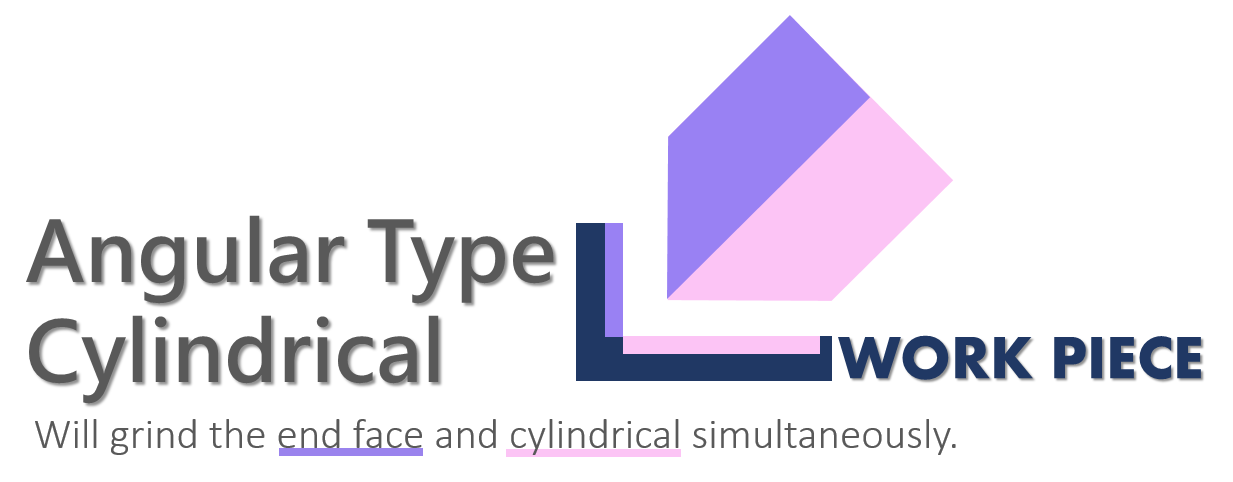

Angular type cylindrical grinding will simultaneously grind both cylinder and end face of the work piece. Due to that the grinding area between wheel and cylinder belongs in a line contacting, however the wheel and end face contact in surface, and the cylindrical grinding wheel was usually been designed in a harder grade. Therefore, it always results in a burned performance to the end face.

In usual, people might try to reduce the wheel speed or softer the wheel grade, however, it might increase the dressing frequency. And undoubtedly it will reduce the quality and efficiency of cylindrical grinding process and decrease the wheel life time. So what should we do to solute this problem?

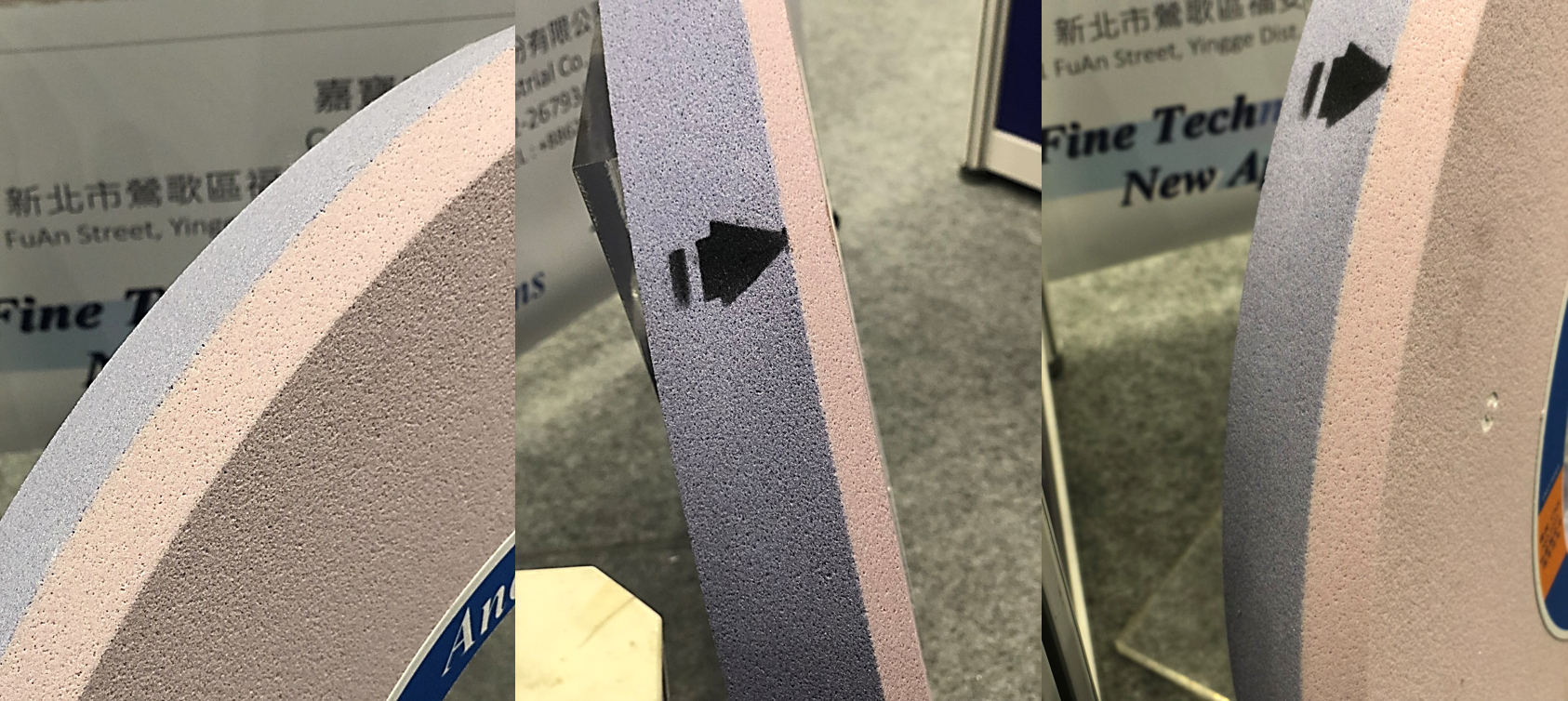

Don’t worry! Anchor has designed the two layers cylindrical grinding wheel for this angular type grinding. We made two different layer of grit size, grade or structure to combine to a T2 wheel through the precise and homogeneous pressing technic, to make sure both cylindrical and end face grinding could simultaneously reach the best quality and efficiency.

The advantages of T2 angular type cylindrical grinding wheel:

- Two layers design, satisfied the requirement of grinding.

- To avoid work burned, reduce dressing frequency.

- Enhance grinding efficiency, simultaneously complete both cylindrical and end face processes.